Moulding Techniques For Ceramic Components

If you need anything more let us know in the comment.

Moulding techniques for ceramic components. Using gel casting we can fabricate strong ceramic components. For example such methods are required for producing advanced high temperature structural parts such as heat engine components. When a ceramic material has been chosen for a specific application the geometry of the component has often been limited by the cost of shaping operations. Ceramic forming techniques are ways of forming ceramics which are used to make everything from tableware such as teapots to engineering ceramics such as computer parts.

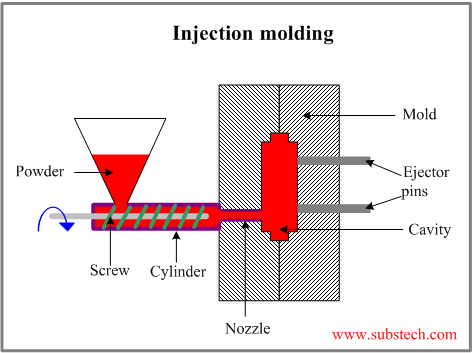

To impart strength the green state components are usually sintered. Ceramic injection molding cim uses ceramic powders such as alumina. Ceramic injection molding is ideal for high volume production of complex tight tolerance components. This can be used to make everyday tableware from teapots to engineering ceramics such as computer parts.

Methods for forming ceramic powders into complex shapes are desirable in many areas of technology. Once the ceramic powders have been compacted to produce the green state component they are approximately 50 70 dense. They are also relatively weak but with care can be machined to quite complex geometries. Technology has jumped forward in great leaps and bounds over the last ten years to arrive at a position were high volume ceramic components can be made using injection moulding techniques.

Technical ceramics enable producing highly temperature biological chemical and wear resistant products that can be used in high tech industries but also for exclusive consumer goods. We have seen all types of ceramic production process techniques in this article. The feed material used for injection molding contains a mixture of ceramic powder with thermoplastic polymer plasticizer. Injection moulding of ceramic components has several major benefits over more traditional manufacturing techniques such as die pressing and green machining.

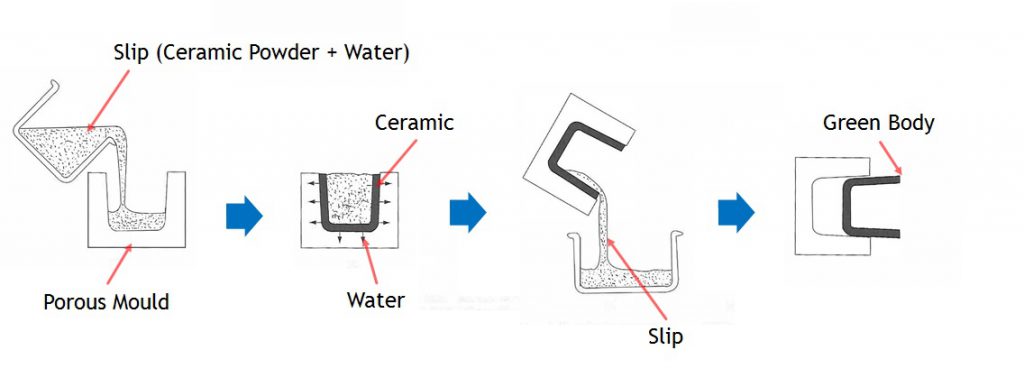

It combines plastic injection molding techniques and performance attributes of ceramic and metal powders. Methods for forming powders of ceramic raw materials into complex shapes are desirable in many areas of technology. Pottery techniques include the potter s wheel slipcasting and many others. We are specialized in development and production of technical ceramics applying ceramic injection moulding cim.