Near Net Shape Manufacturing Of Ceramics

Many of the products produced by blasch have complex shapes that could not be produced with other existing ceramic technology.

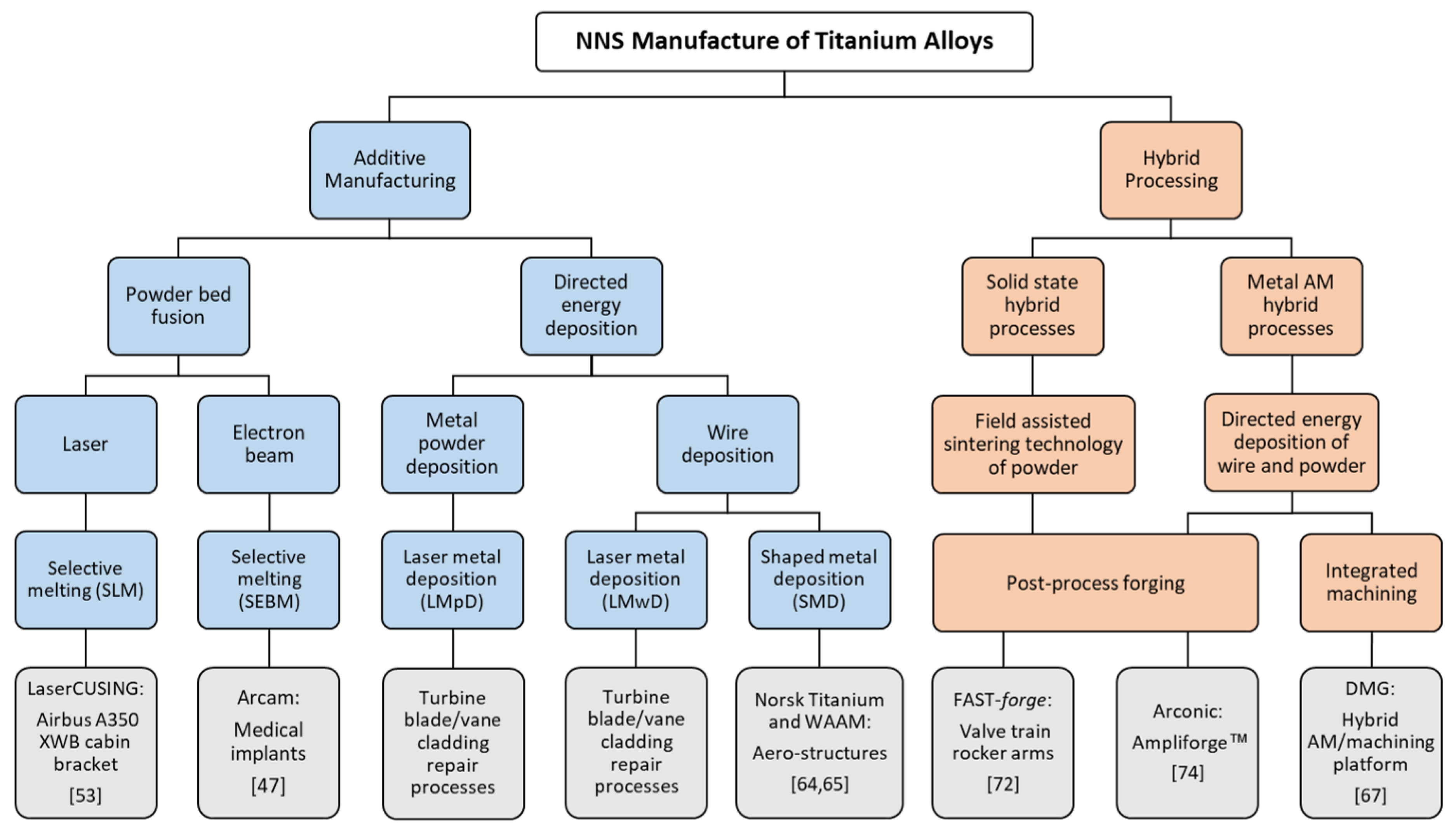

Near net shape manufacturing of ceramics. Net shape manufacturing focuses on the manufacture of discrete parts to net or near net dimensions. Spark plasma sintering sps is the process of consolidating metal and ceramic powders using high temperatures and pressures. The name implies that the initial production of the item is very close to the final net shape reducing the need for surface finishing. It is the aim of this paper to discuss novel approaches for near net shape manufacturing of ceramic and ceramic composite components based on infiltration techniques reaction mechanisms and porosity formation processes.

The first step in the manufacturing process figure 1 is the careful choice of the ingredients of the compound that in general consists of a polymeric binder system and the metal or ceramic powder. Near net shape nns manufacturing engineered parts have critical accuracy and surface roughness requirements specs that ensure the part fits correctly into a larger assembled product and performs as designed. Powder injection molding is a near net shape manufacturing technique for complex metal or ceramic components. In the past a ceramic component has been 2x to 5x more expensive than a comparable steel component.

Near net shape is an industrial manufacturing technique. The accuracy ensures parts and surfaces mate correctly and surface roughness influences how the surfaces interact. Extremely complex and high tolerance ceramic parts designs often require follow up processing. Structural development and properties of.

Traditional ceramic machining requires diamond tooling and longer processing time. Basic aspects of shrinkage reduction. Novel polymer derived ceramic hard materials p 1985. Reducing traditional finishing such as machining or grinding eliminates more than two thirds of the production costs in some industries.

Near net shape manufacturing of polymer derived ceramics p 1981. Ceramco s staff is highly skilled in the machining glazing and assembly of virtually any oem ceramic part we manufacture. Colloidal processing and sintering behaviour of silicon nitride composites with nanosized alumina p 1989. That constitutes about 80 of the cost.