Near Net Shape Manufacturing Of Polymer Derived Ceramics

H 2 o co 2 ch 4 etc at elevated temperatures 1000 c in an inert atmosphere.

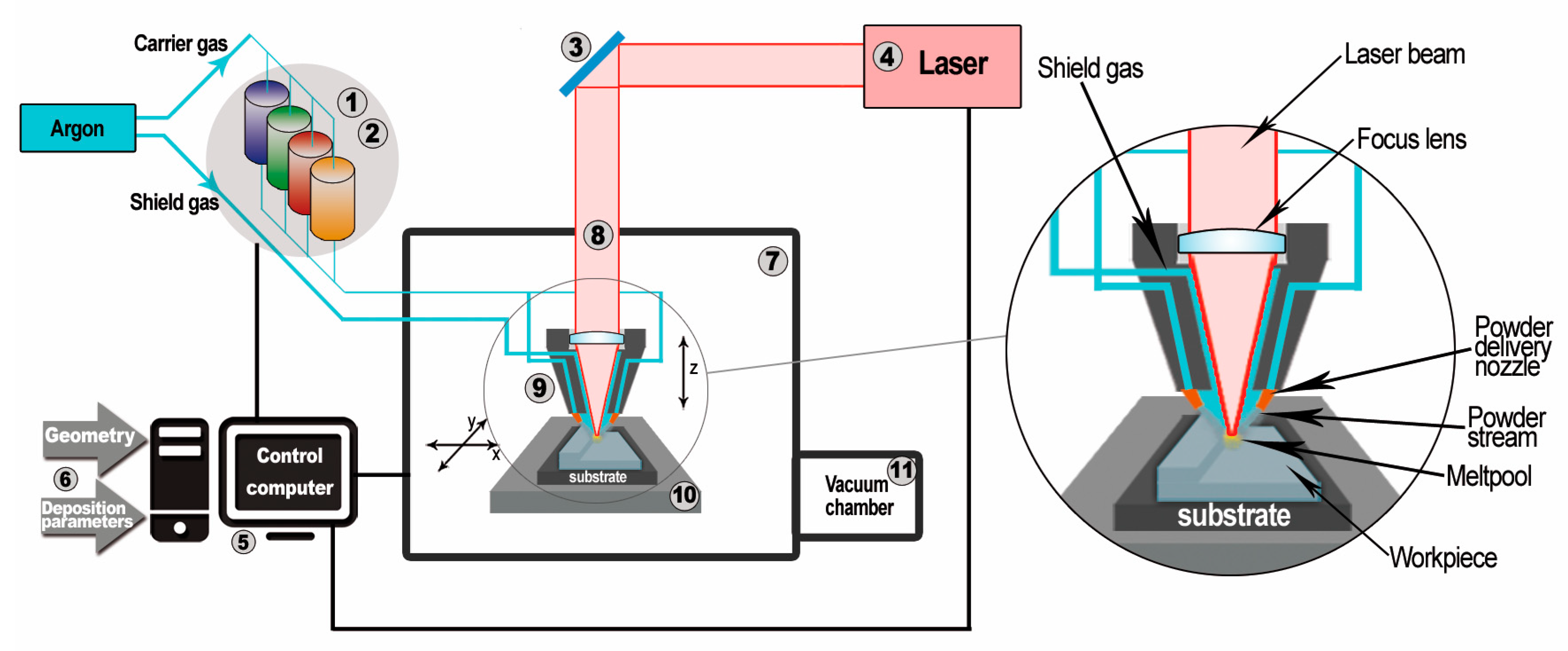

Near net shape manufacturing of polymer derived ceramics. A uv curable preceramic monomers are mixed with photoinitiator. Near net shape manufacturing of polymer derived ceramics p 1981. C a preceramic polymer part is obtained. Novel polymer derived ceramic hard materials p 1985.

Suttor non oxide and oxide ceramics from preceramic polymers for composite components engineering ceramics 96. 1 additive manufacturing of polymer derived ceramics. B the resin is exposed with uv light in a sla 3d printer or through a patterned mask. Colloidal processing and sintering behaviour of silicon nitride composites with nanosized alumina p 1989.

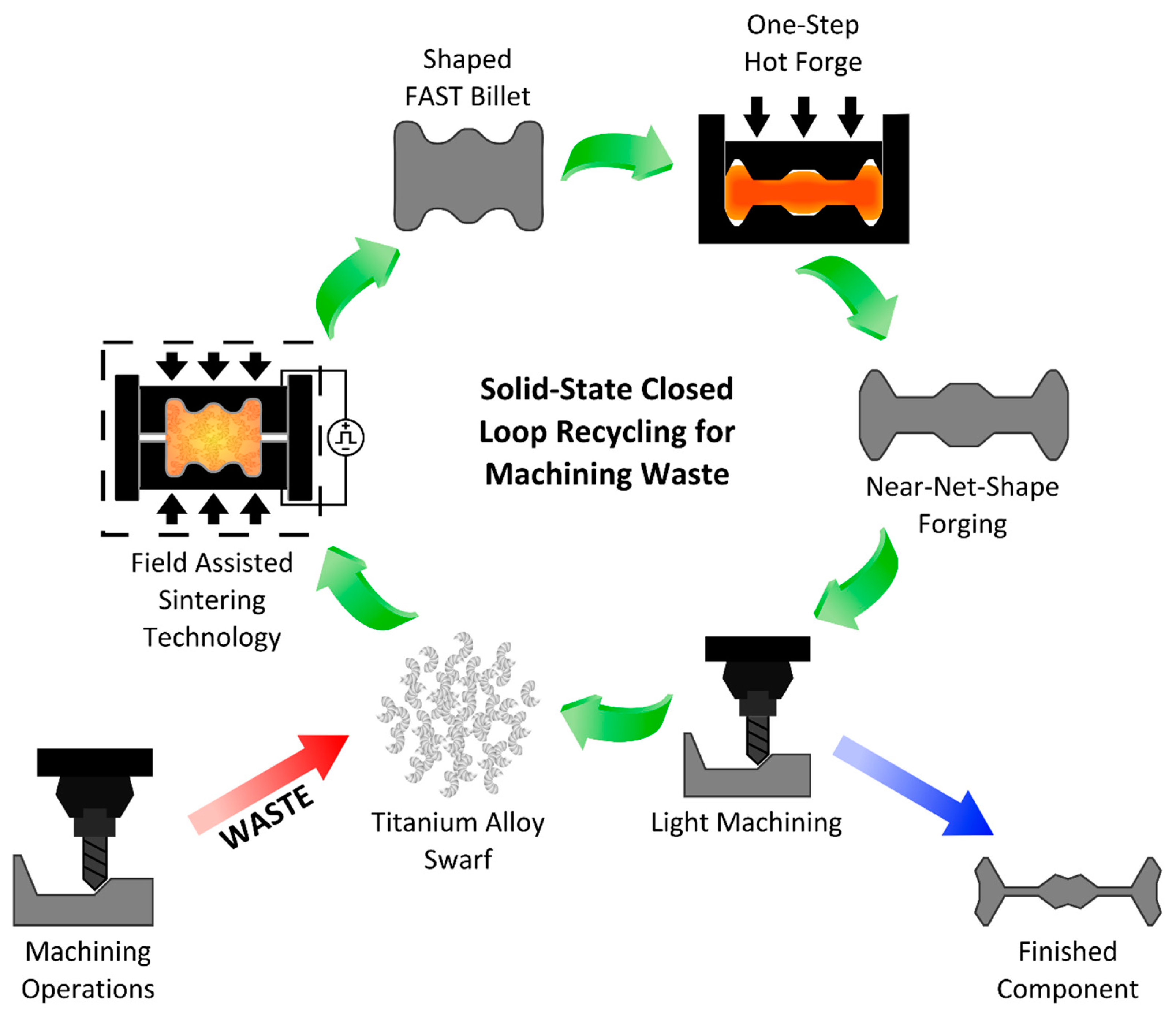

Processing scheme of polymer filler derived ceramics. 2 summarizes the processing scheme for polymer filler mixtures used as starting materials for near net shape manufacturing of polymer derived ceramics. Near net shape forming of bulk ceramic components even with complex geometry is possible making novel applications of polymer derived bulk materials in biomedical electrical and mechanical fields highly interesting. Download high res image 40kb download.

Pyrolytic conversion of preceramic polymers loaded with active filler particles offers the possibility of near net shape manufacturing of bulk ceramic components from polymers. Structural development and properties of. During pyrolysis may form carbide nitride or oxide reaction products in the polymer derived amorphous. Peter greil near net shape manufacturing of polymer derived ceramics journal of the european ceramic society 10 1016 s0955 2219 98 00129 0 18 13 1905 1914 1998.

Near net shape manufacturing of polymer derived ceramics. D pyrolysis converts the polymer into a ceramic. After achieving sufficient cross link density from the layer by layer sla operation near net shape cured preceramic polymer components are then converted to a ceramic by driving off volatile organic species from the polymer network e g. It is the aim of this paper to discuss novel approaches for near net shape manufacturing of ceramic and ceramic composite components based on infiltration techniques reaction mechanisms and porosity formation processes.