Neck Ceramics Definition

A high fire clay that matures and fires to cone 8 or higher.

Neck ceramics definition. Porous pottery that matures when fired at a low temperature below 2000 degrees stoneware. Batch a mixture of weighed materials such as a batch of glaze or slip or a clay body. Bats are used to throw pieces on that would be difficult to lift off the wheel head. A ceramic raw material has high percentage of silica and alumina.

Ceramics definition the art or technology of making objects of clay and similar materials treated by firing. Small triangular cones made of ceramic materials that are compounded to bend and melt at specific temperatures thus enabling a potter to determine when the firing is complete. Conservation and restoration of ceramic objects is a process dedicated to the preservation and protection of objects of historical and personal value made from ceramic. The coarse particles open the green clay body to allow gases to.

Bat a flat disc made out of plaster wood or plastic which is affixed to the wheel head with clay or pins. For example clay has chemically bonded water in it which will cause it to slake down disintegrate when a dried clay object is put in water. Technically ceramics are those things made from materials which are permanently changed when heated. The art of making objects by shaping pieces of clay and then baking them until they are hard 2.

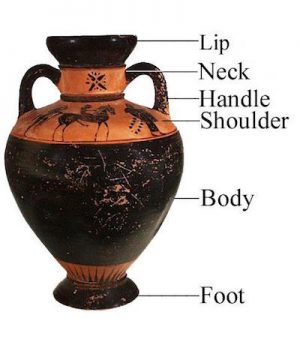

Once heated fired to between 660 and 1470 f 350 and 800 c the clay is converted to ceramic and will never dissolve again. Ceramic foam is an important part of porous ceramics and the open cell type of ceramic foam which is a new type of highly porous ceramics has a three dimensional reticulated structure with connective pores resulting in great specific surface area high fluid contact efficiency and a small loss of fluid pressure 26 27. Although this term is usually used interchangeably with ceramics it more precisely refers to ceramic objects that have a container shape such as pots planters and tureens. It can be used in pottery and sculpture to add a gritty rustic texture called tooth.

This prevents defects such as cracking crow feet patterning and lamination. It also can be used to refer to factories that produce pottery pieces. It also reduces shrinkage and aids even drying.