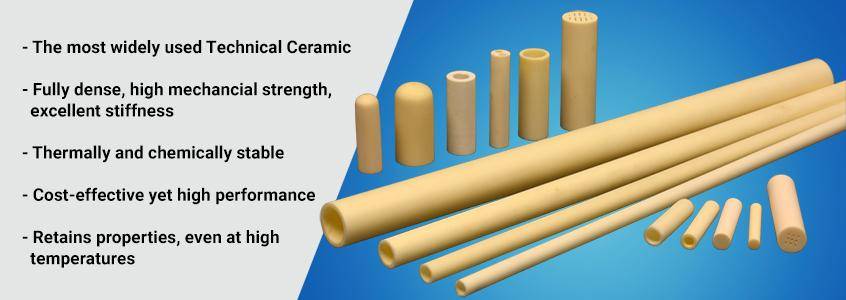

Non Porous Alumina Ceramic Tubes

Multidirectional cnt growth has been achieved on a porous alumina foam coated with fe catalyst by ald chen et al 2014a which is a form of cvd that involves the sequential use of a gas phase chemical process in ald the precursors react with the.

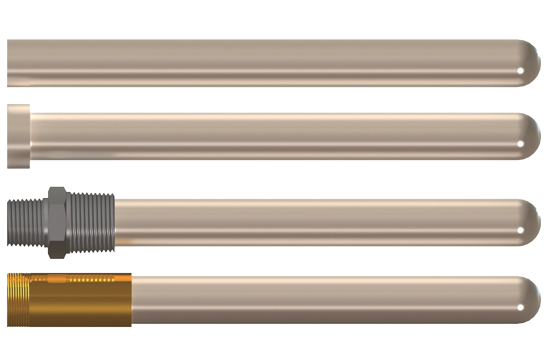

Non porous alumina ceramic tubes. Alumina aluminum oxide is used in a variety of applications up to 800 c to replace metal plastic polymer or fabric. Mcdanel advanced ceramic technologies llc is a leader in developing and manufacturing the highest quality ceramic tubes and ceramic components. Not for use with ceramic coated aluminum or 300 series stainless steel shafts. Enhance performance and product life by using the material best suited to your application.

Our rugged alumina porous ceramics are durable long lasting solutions that are not only mechanically strong mor up to 30 mpa but also inert and cleanable. Chung in carbon composites second edition 2017. Sentro tech offers broad range of porous ceramic tubes and parts to meet your various applications. Alumina single bore tubes are available in many sizes configurations and materials to meet unique requirements.

For technical drawings and 3 d models click on a. Porous ceramic tubes sheets bars more. A ceramic liner makes high speeds as well as rapid acceleration and deceleration possible. This material is versatile enough to be used for products in a variety of applications such as laser power tubes telecommunications components aerospace components automobile components domestic product components process equipment components.

Because of our core focus on ceramic technologies mcdanel is uniquely positioned to provide you with superior products and dedicated service for an unparalleled range of applications. In stock and ready to ship. Bearings are for use with round end supported shafts. Dense non porous and vacuum.

Coorstek offers a wide variety of tubes and rods manufactured from high performance technical ceramic materials including alumina zirconia and silicon carbide. Choose from our selection of nonporous alumina ceramic easy to machine alumina ceramic and more. We work with oem and end users worldwide to provide solutions for filtration separation purification diffusion and fluidization. Find full list of dimensions available.

609 397 8330 or 609 397 8341 fax. They are self aligning to compensate for shaft misalignment and have end seals to keep lubricant in and dirt out. Alumina ceramic tubes have exceptional hardness and strength resistance to chemical attack and wear low dielectric loss and excellent electrical insulation properties. Additionally alumina can be metallized for brazing to other metals highly polished and comes in a variety of purities depending on it use.