Nox Scr Ceramic Carbon

By selective catalytic reduction with catalytic ceramic filter elements september 28 2016 rod gravley.

Nox scr ceramic carbon. A new method for preparing vanadium oxide supported on carbon ceramic cellular monoliths is described. In the scr process the reducing agent reacts with nox to convert the pollutants into nitrogen n2 h2o and tiny amounts of carbon dioxide co2 which is then expelled through the vehicle tailpipe. Selective catalytic reduction substrate ceramic used in diesel truck. This includes a support oxidation step with hno 3 followed by ionic exchange with a naoh solution equilibrium adsorption impregnation of vo 2 and thermal treatment.

3m mn production 25 000 pm nox two projects calgon carbon az reactivation furnace 25 400 pm so2 hcl first industry application caem port of la diesel engine exhaust 25 900 pm nox ships at dock. Euro 4 standard scr ceramic catalyst. Our company has successfully developed many types of three way catalytic converter which are suitable for cars in all types and meet the emission standard. As customers requests all kind of three way catalytic converter can be explored and produced.

Scr catalyst can removes nitrogen oxides nox from diesel vehicles. Selective catalytic reduction scr is the process of nox reduction or denox. Find complete details about selective catalytic reduction substrate ceramic used in diesel truck substrates ceramic scr scr urea from other auto engine parts supplier or manufacturer pingxiang hualian chemical ceramic co ltd. Selective catalytic reduction scr is a means of converting nitrogen oxides also referred to as no x with the aid of a catalyst into diatomic nitrogen n 2 and water h 2 o a reductant typically anhydrous ammonia aqueous ammonia or urea solution is added to a stream of flue or exhaust gas and is adsorbed citation needed onto a catalyst as the reaction drives toward completion carbon.

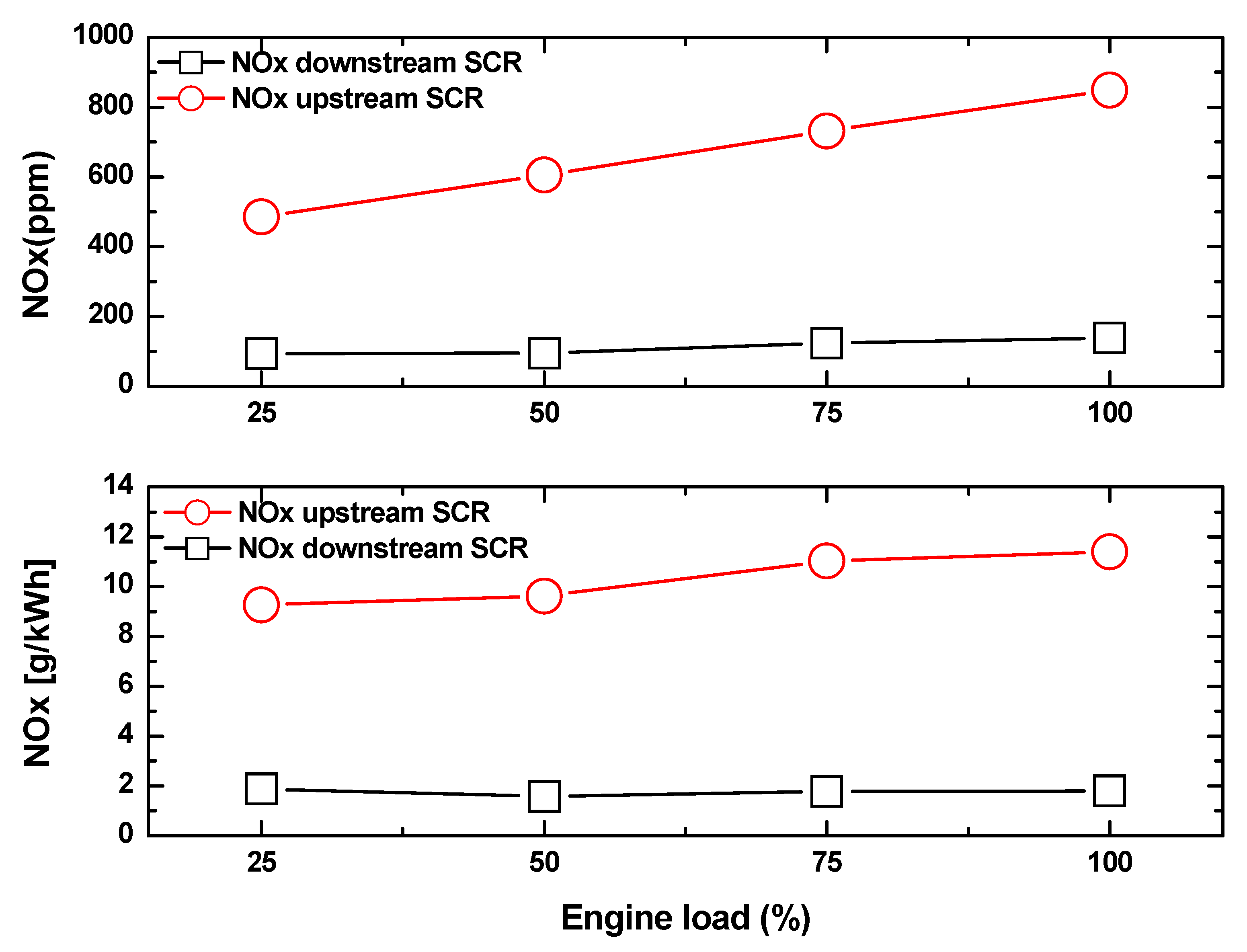

To remove nox catalytic ceramic filter elements are manufactured with nano bits of scr selective catalytic reduction catalyst embedded in the walls about 3 4 inch 20 mm thick. These filters achieve nox removal with over 90 efficiency. Selective catalytic reduction with nh3 nh3 scr is the most efficient technology to reduce the emission of nitrogen oxides nox from coal fired industries diesel engines etc. Nscr reactions require that the oxygen content in the exhaust gas be very low on the order of 1 o2.

That is you can inject a water solution of ammonia ammonia as a dry gas or urea. Selective catalytic reduction scr involves the use of a catalyst that is selective to promote the reaction of ammonia and n0x to form nitrogen and water. Although v2o5 wo3 moo3 tio2 and cha structured zeolite catalysts have been utilized in commercial applications the increasing requirements for broad working temperature window strong so2 alkali heavy metal. As a result an active catalyst for low temperature selective catalytic reduction scr reaction is obtained.