Oil Water Separation Ceramic Membrane

Oil water separation degreasing bath treatment using ceramic membrane or oily coolant waste processing.

Oil water separation ceramic membrane. The brains of the system intelliflux adapts and adjusts operating conditions and membrane cleaning protocols if the rate of membrane fouling increases or decreases. Reported herein is a novel ultrarobust and biomimetic hierarchically macroporous ceramic membrane that can achieve a high efficiency of up to 99 98 for oil water separation while the efficiency remains nearly unchanged even after 10 rounds of use and storage for up to 4 months. However traditional membranes suffer from membrane fouling both on surfaces and in internal structures which significantly limits their service time and degrades separation. Continuous process flux for oil water separation is recorded between 200 2000 l m h.

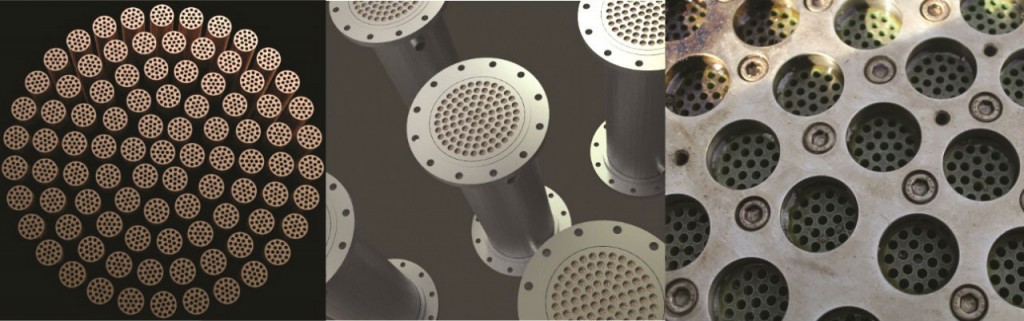

Atech produces a wide variety of ceramic membranes for different purposes as this method of filtration is used in different industries ranging from the food to the chemical and environmental industries. The team has separated batches of oil water mixtures and emulsions and shown that a continuous flow system can operate for more than 100 hours without fouling the membrane or slowing down. Membrane techniques have been widely employed for water purification and are very effective in separating stabilized oil emulsions especially for removing oil droplets. The macroporous ceramic membrane is prepared by combining surface hydrophobic coating with an emulsion assisted.

In the batch mode of operation synthetic o w emulsions were subjected to. This review focuses on the discussion of various electrospun flexible membranes assorted into three categories including polymer based membranes ceramic based membranes and carbon. Ceramic membranes are a proven method of oil water emulsion separation atech innovations produces top quality yet very affordable modules. The hydrophilic side of jcm has a better anti fouling property than icm does when dealing with o w emulsions.

Up front mechanical oil water separation and slop oil dewatering protect downstream ceramic mf uf membranes while enabling recovery of black oil. In this review we aim to present the design and fabrication of electrospun flexible nanofibrous membranes with special wettability for oil water separation. In the metal processing industry degreasing is an important step for preparing metal components for further treatments. Depending on the oil type.

Due to the unique hydrophilic properties of silicon carbide it is possible to obtain higher water fluxes on liqtech s sic based ceramic membranes than any other membrane material. Alternatively the hydrophobic side can separate w o.