Non Porous Alumina Ceramic

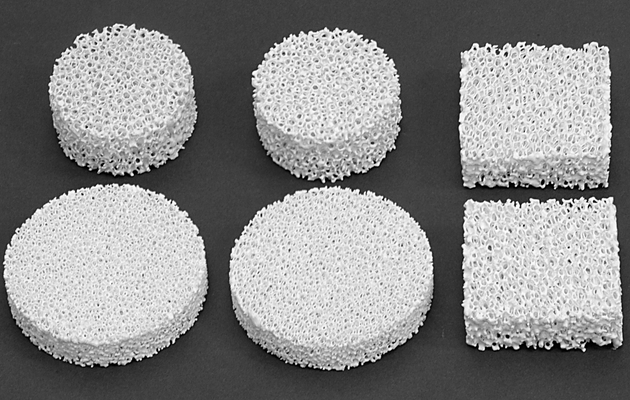

Flowable and stable porous alumina ceramics suspensions containing 36 vol alumina and 25 vol of expandable polymer spheres or glassy carbon as sacrificial template were gel cast to produce green bodies following our previous work.

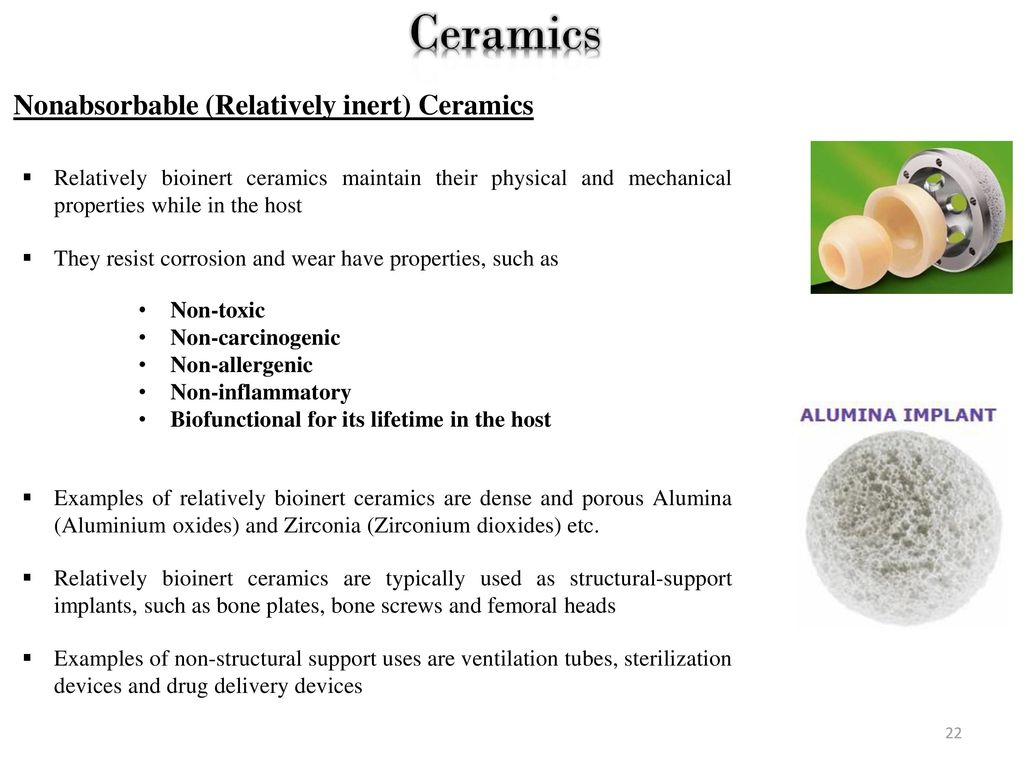

Non porous alumina ceramic. Features of this material include. Exceptionally high dielectric strength. Aluminium trihydrate is the main raw material that is a pore forming agent and. This is a top quality alumina ceramic of 97 6 al 2 o 3 content widely used for high integrity components where its exceptional electrical and thermal properties are essential to operational stability and reliability.

Chung in carbon composites second edition 2017. 2 1 9 carbon grown on ceramic 2 1 9 1 carbon nanotubes grown on alumina. 15 the gel cast bodies were unmolded and kept at 25 c at a relative humidity of 25 for 85 hours. Alumina based foam filters are used for primary aluminum casting foundry castings of steel aluminum and other non ferrous alloys investment casting and chemical processing.

Alumina aluminum oxide is used in a variety of applications up to 800 c to replace metal plastic polymer or fabric. Almatis aluminas for porous ceramic applications include soft and hard calcined aluminas available in continuous ground and batch ground versions. The performance of porous ceramics is highly dependent on the pore forming mechanism and material formula which may render it difficult to obtain controllable properties. Our rugged alumina porous ceramics are durable long lasting solutions that are not only mechanically strong mor up to 30 mpa but also inert and cleanable.