Non Conductive Ceramic Coating

Iso 9001 2000 certified custom manufacturer of non conductive ceramic insulating coatings for dielectric applications.

Non conductive ceramic coating. There are a wide range of ceramic coating materials that can be applied to metal components in order to enhance their functional properties. Plasma spraying a non conductive ceramic coating onto a connector metal plug body is the latest and perhaps best effort to eliminate galvanic action at this interface area. These hybrid coatings have many applications in a variety of applications and industries. Conductive and non conductive coatings that generally incorporate such conductive fillers are used promote or limit the flow of heat or electrical current into or away from the object that is coated.

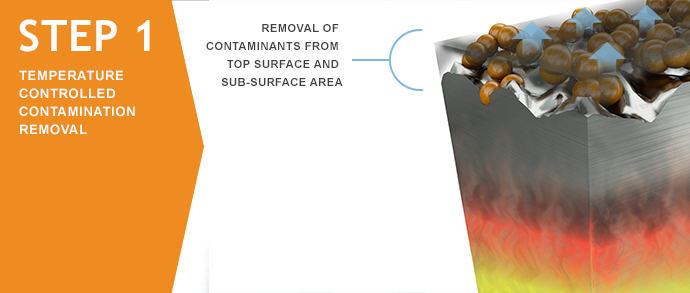

Ceramic by nature is an excellent conductor of heat f lon ceramic coatings can be applied in many applications where one or more of the following properties are required. Features of dielectric coatings include abrasion. Benefits of non conductive coatings. Zhang et al 22 made a comparative study of diamond grinding of ceramic coatings on a.

Most ceramic coatings are electrically nonconductive making them excellent insulators have a significantly higher level of abrasion resistance than most metals and are capable of maintaining their integrity under severely elevated temperatures. When you utilize non conductive coating services from a a coatings there is a host of benefits you stand to gain. Most non conductive coatings are organic in nature and achieve their insulative properties by being devoid of conductive metals such as copper zinc and nickel. Wide variety of metal metal alloy carbide matrix ceramic and polymer coatings available with these properties as well as combination coatings composed of thermal spray and polymer coatings.

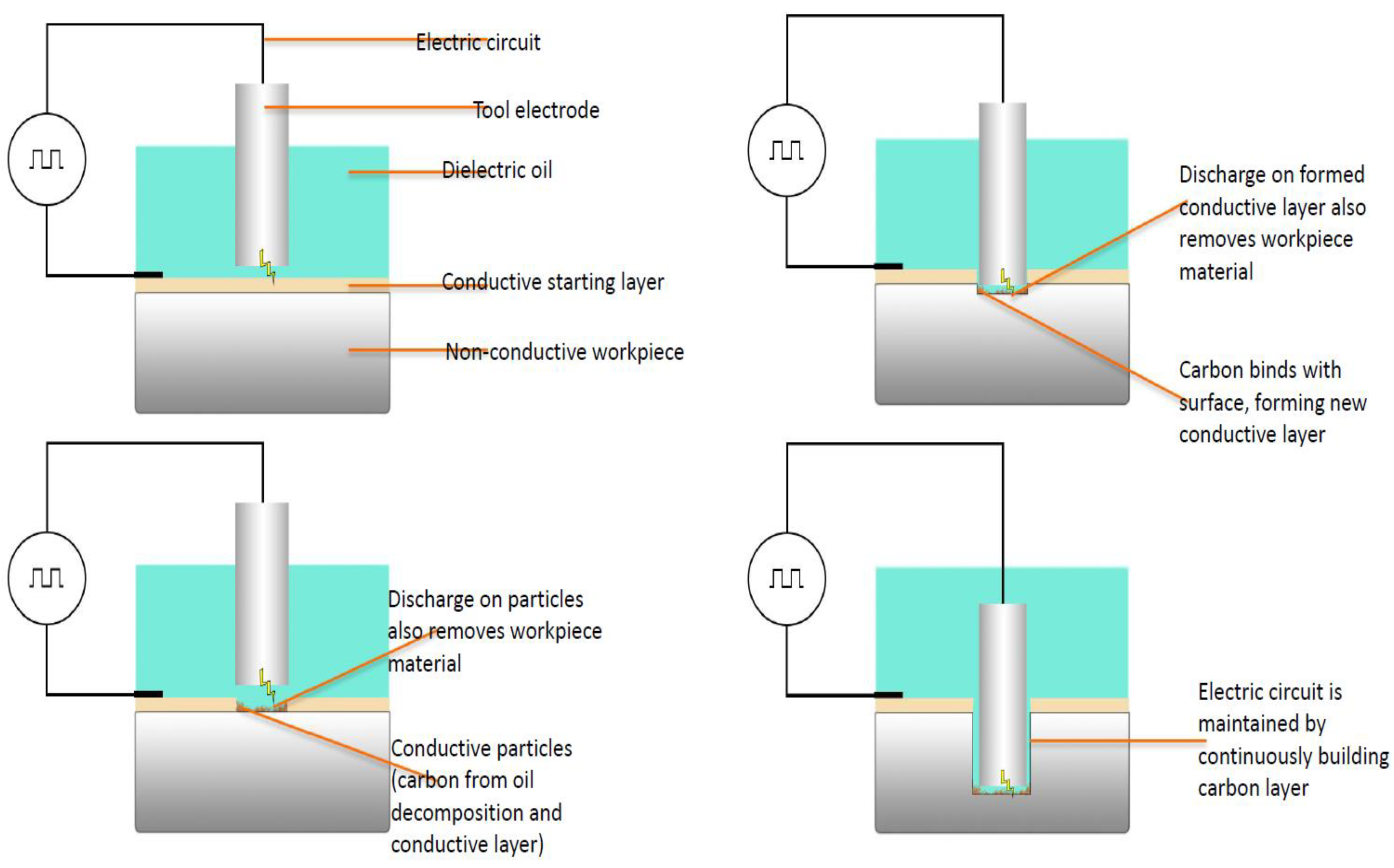

Non conductive coatings are specialized coatings that limit the transfer of heat or electricity to the metal substrate with the coating applied. Ceramic coatings 22 include a large group of subspecies such as chemical vapor deposited silicon carbide plasma spray deposited aluminum oxide and plasma spray deposited chromium oxide. Emi shielding emi shielding products conductive coatings cosmetic coatings chrome effects and scratch resistant coatings non conductive coating products emi shielding solutions. This non conductive spray coating may also be needed when repairing cars especially parts exposed to heat.

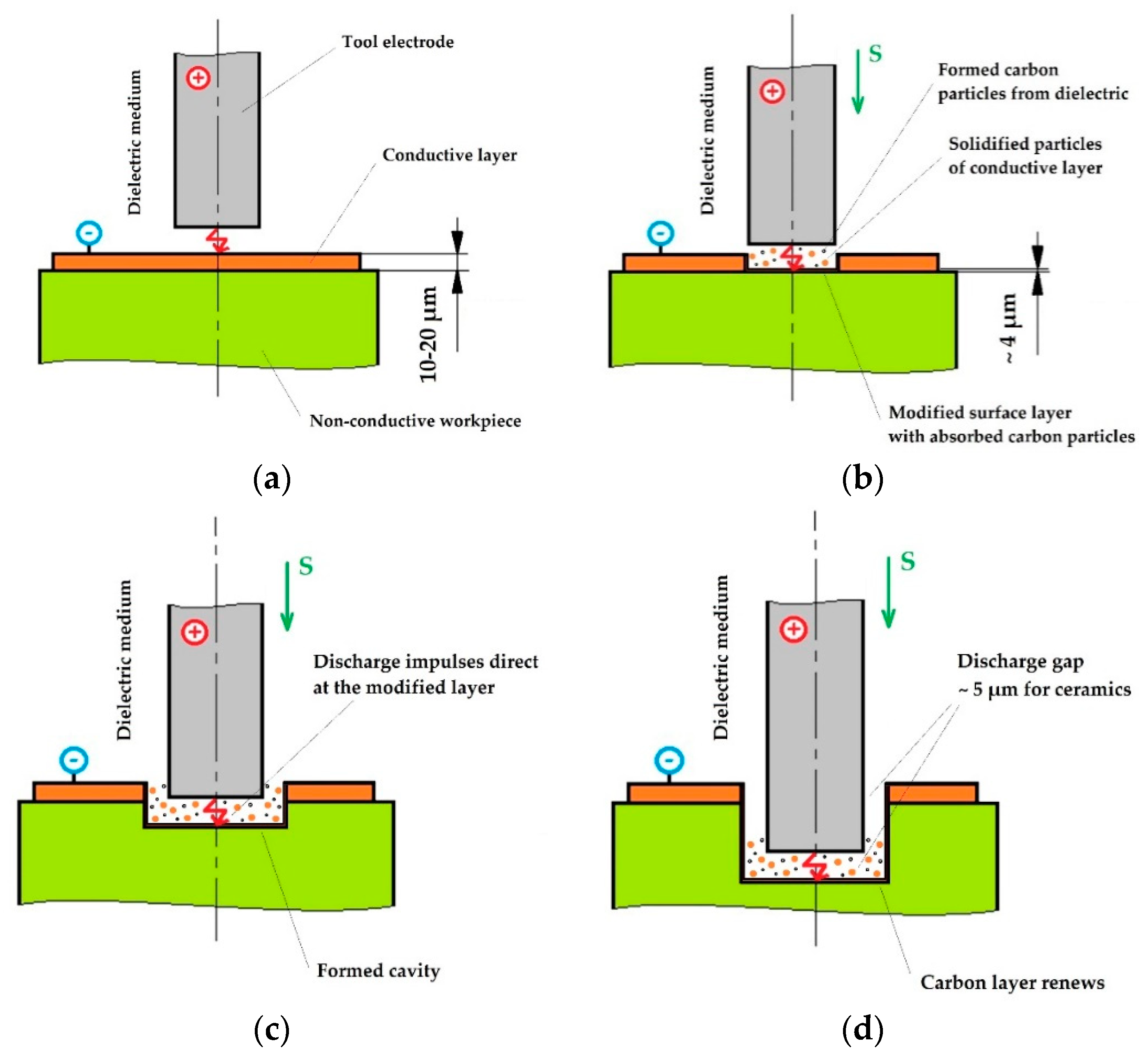

Dielectric coatings are available with 0 05 0 15 friction coefficient minus 400 degrees f to plus 2400 degrees f operating temperature 0 0002 in. Ceramic plasma sprayed coatings ceramic coatings are the most common means of industrial electrical and thermal insulation in industries such as automotive aviation and machine building. In order to achieve the required quality efficient machining of these ceramic coatings is still under development.